Revolutionising food packaging with rPET

RePETec is a thin-wall container solution for a circular economy

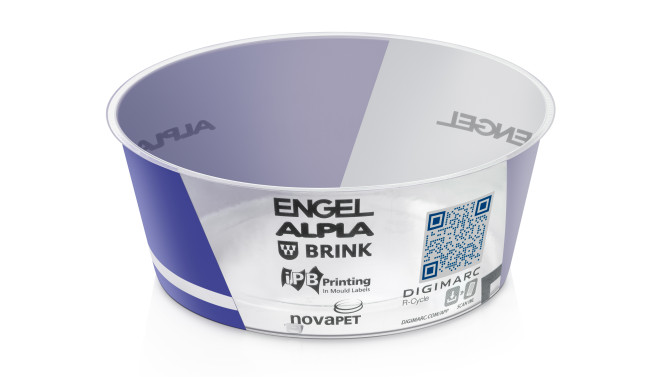

In response to the growing demand for sustainable food and dairy packaging, ALPLA has developed a pioneering solution: RePETec thin-wall containers. Produced using a single-step injection moulding process, these ultra-thin containers represent the latest in rPET innovation. Launched at the K exhibition in collaboration with our valued partners, this advancement positions ALPLA as a leader in eco-friendly, high-performance packaging for the modern B2B landscape.

Benefits of rePETec rPET thin-wall containers

Achieving sustainability goals through innovation

Why rePETec? Sustainability and compliance have become critical priorities in the packaging industry, driven by initiatives like the European Plastics Pact aiming for 30% recycled content and full recyclability by 2025. RePETec containers are designed to meet these demands offering a fully recyclable solution that incorporates up to 100% rPET. Creating an adaptable, eco-conscious alternative to traditional materials. This allows businesses to enhance their environmental credentials, avoid regulatory penalties, and stay ahead in sustainable packaging innovation.

Reasons for switching to our thin-wall packaging solution

Customer focused benefits

Aligned with B2B needs rePETec containers provide the same familiar handling as conventional PP and PS options, while outperforming them in terms of performance and sustainability:

-

High Oxygen Transmission Rate (OTR): Up to 20 times better than PP and 30 times better than PS, ensuring longer shelf life for products.

-

Water Vapour Transmission Rate (WVTR): Matches PS and is 1.5 times lower than PP, ideal for moisture-sensitive items.

-

Labelling and decoration options: Diverse in-mould labelling (IML) options are available to meet different regional recycling standards, from floatable labels for European markets to wash-off ink labels for the US.

-

Ease of processing: RePETec’s standardised diameters and specifications match existing bottling line requirements, reducing transition costs and maintaining production efficiency.

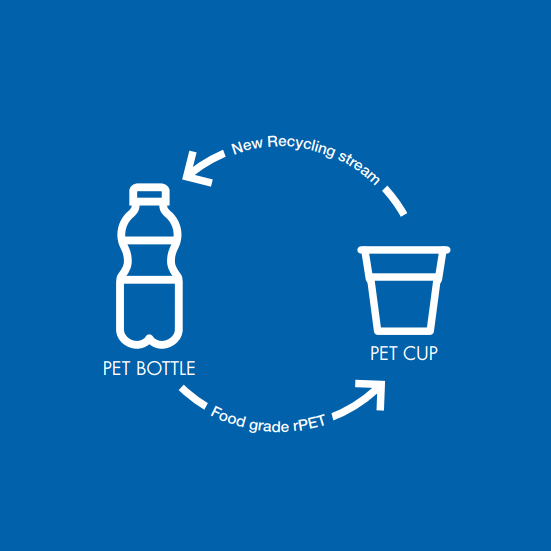

From bottle-to-cup and cup-to-bottle recycling

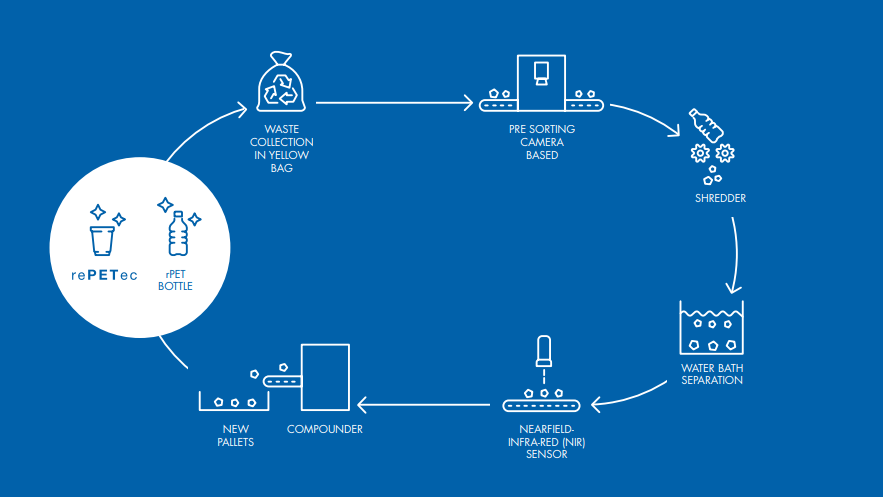

Setting a new standard: The rePETec innovation is more than just packaging – it's a commitment to reshape the lifecycle of plastic packaging. While traditional recycling is primarily bottle-to-bottle, ALPLA’s technology enables bottle-to-cup and even cup-to-bottle recycling. This breakthrough helps close to close the loop for non-bottle packaging, offering a genuine path to circularity for manufacturers. The established recycling infrastructure of PET makes it uniquely positioned to become a mainstream material, helping companies achieve both cost-effectiveness and environmental responsibility.

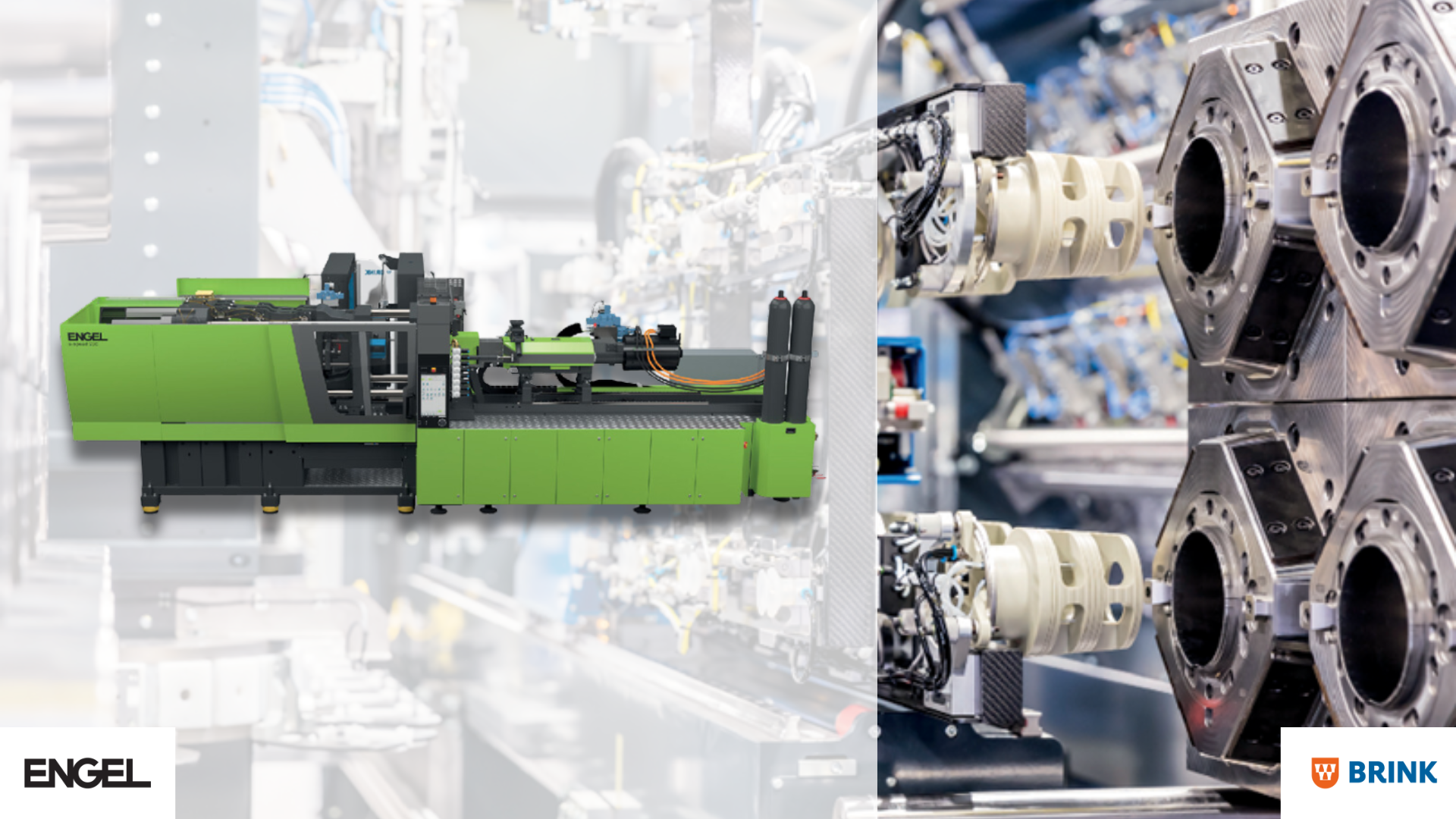

Precision engineering and trusted partnerships

Our work with leading industry partners ENGEL, Brink, and IPB Printing is a testament to ALPLA’s dedication to top-tier engineering and sustainability. ENGEL’s advanced PET injection technology and our modified rPET material enable ultra-thin walls as slender as 0.32 mm while ensuring durability and improved performance. Combined with Brink’s moulding expertise and IPB Printing’s label innovations, we’ve created a solution that is both high-performing and highly recyclable.

Specifications tailored for food packaging standards

From 100–500 ml, ideal for food and dairy applications.

0.32 mm wall thickness for reduced material usage.

Hot fill up to 55 °C; sterilisation options include UV-C/pulsed light.

Various sealing foils available, designed for recyclability without aluminium. Clear and foamed.

Cyclos-HTP certified demonstrating compliance with the highest food safety standards.

The thin-wall injected rePETec offers a highly recyclable, closed-loop solution to packaging waste

Fully recyclable rPET yoghurt cups in production 2025

Following a successful test phase, ALPLA and INTOPACK will start series production of thin-walled rPET yoghurt cups in Q4 2025. Available in two standard formats, 180 and 300 millilitres, the cups can also be customised for filling volumes from 100 to 500 millilitres. With ultra-thin 0.32 millimetre walls and integrated in-mould labelling, these innovative cups combine sustainability with practicality. Find out how this innovative dairy packaging solution meets industry challenges and supports a circular economy.

Contact us for inquiries

Explore with us innovative and eco-friendly packaging solutions. We are looking forward to assisting you in achieving your packaging goals. Reach out today to learn more and be sure to check out our blog for the latest insights and updates.

Explore circular design with ALPLA

Witness the innovation behind our sustainable plastic packaging solutions. Join ALPLA's family of pioneers on a journey where creativity meets sustainability.